Features

Features

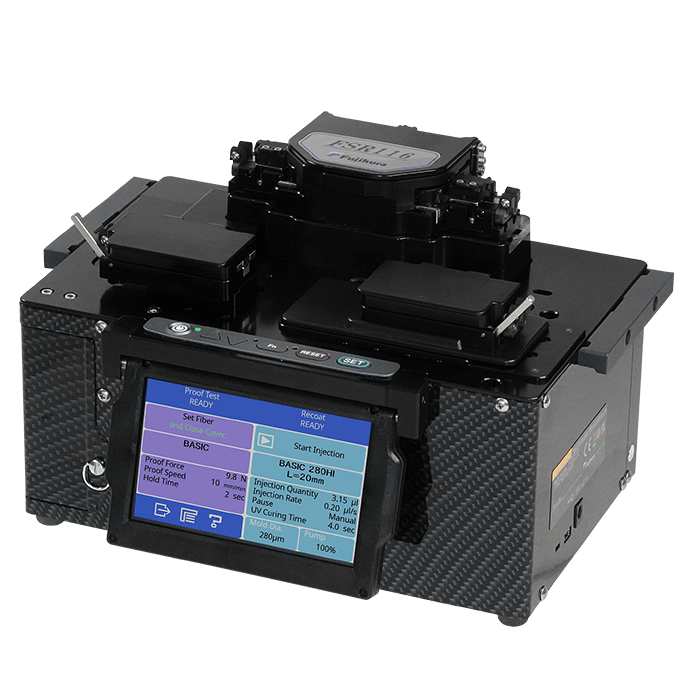

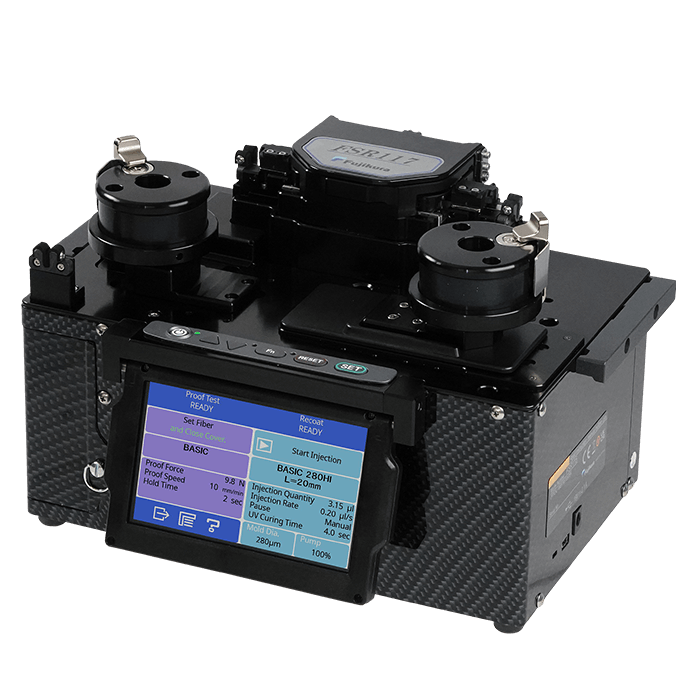

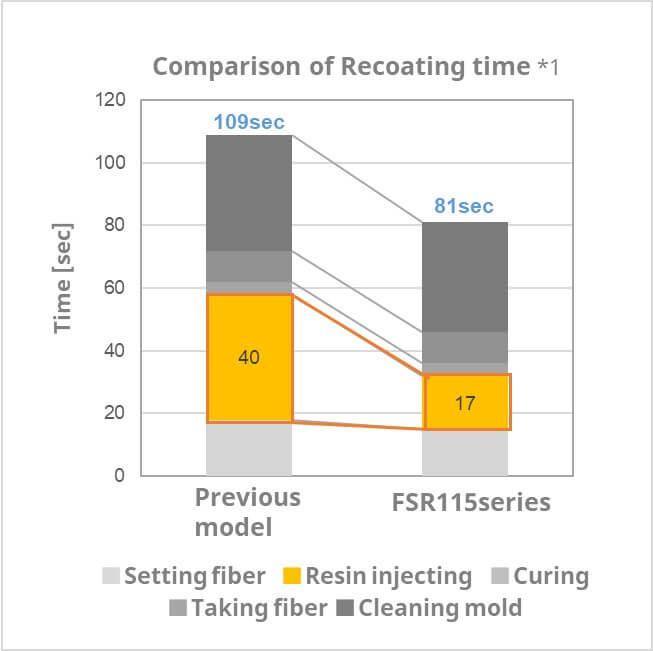

Faster

Shortened UV curing resin injection time

New designed pump provides shorter UV resin injection time. It also provides 25% shorter total recoating time than previous model.

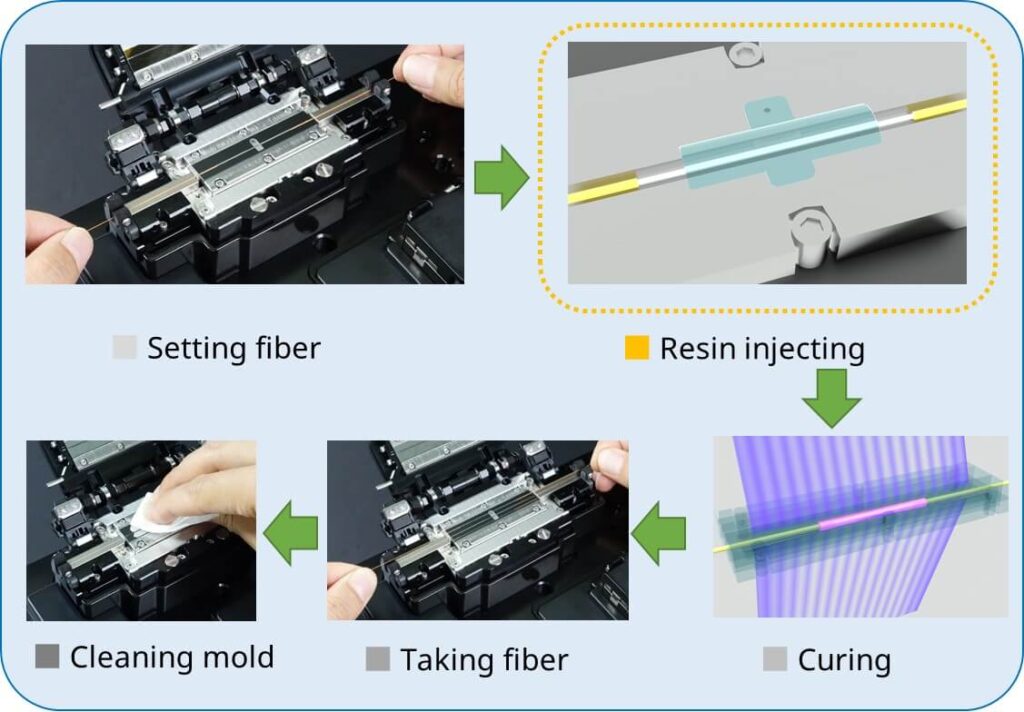

How to recoat

*1: Test condition:

(1) UV recoat Resin:Japan Fine Coatings Co., Ltd. 950Y200 or Luvantix ADM Ltd. PC-373LD

(2) Recoat diameter:280µm

(3) Recoat Length:20mm

(4) Fiber:Clad Diameter 125µm/Transparent UV 250µm Coating Diameter, Coating Stripping length 16mm

(5) Environmental Condition: 25℃。

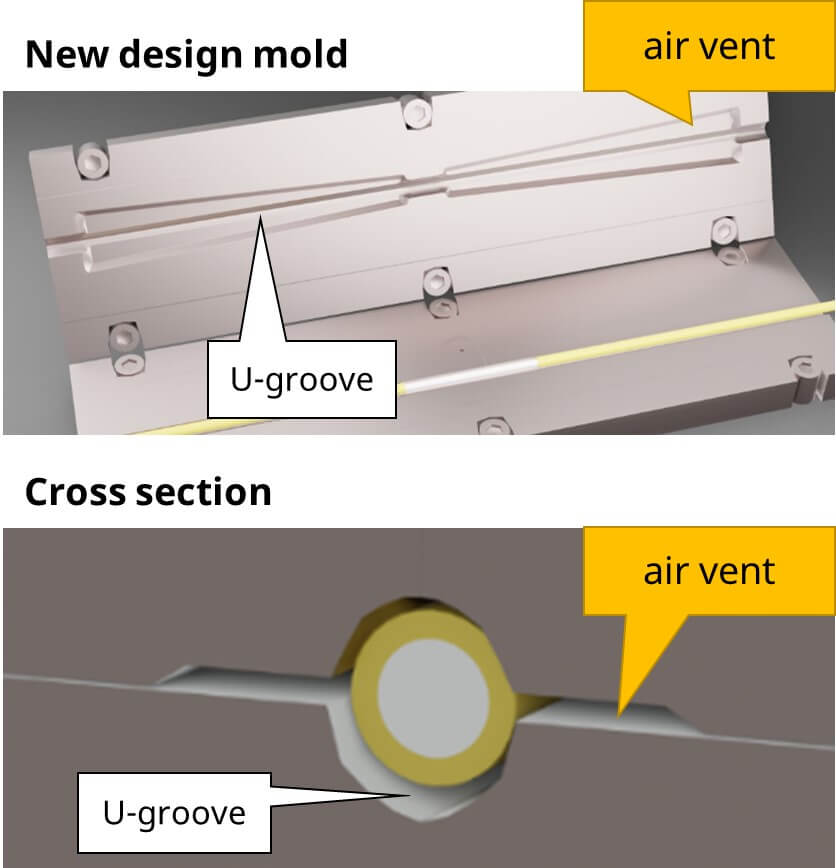

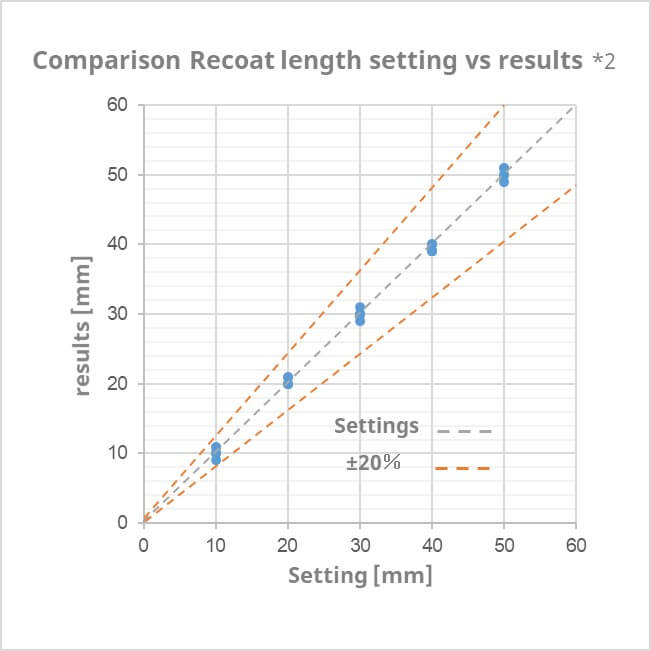

More accurate

Improved recoating length repeatability

The recoat mold has slight steps on the U-groove to provide an air vent. It helps to improve the recoating length repeatability, as well as the ability to reach a max. 50mm length.

*2: The table does not guarantee the recoat length accuracy.

Test condition:

(1) UV recoat Resin:Japan Fine Coatings Co., Ltd. 950Y200

(2) Recoat diameter:280µm

(3) Recoat Length:10-50mm

(4) Fiber:Clad Diameter 125µm/Transparent UV 250µm Coating Diameter, Coating Stripping length 60mm

(5) Environmental Condition: 25℃

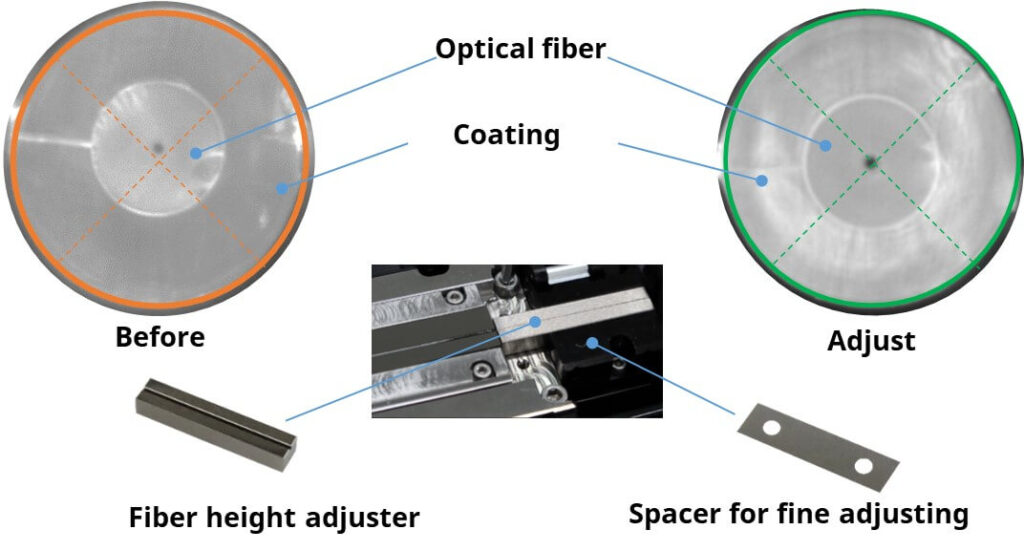

More user friendly

Fiber and recoating centering adjustment is now possible by the user

The Fiber height adjuster enables the adjustment of fiber diameter centering by setting the fiber to be centered in the mold.

The spacers allow for fine tuning based on original fiber coating variations.

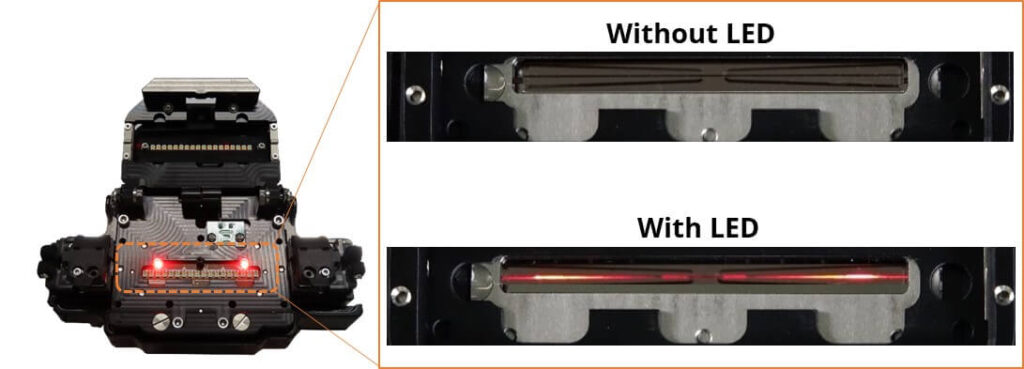

Clear observation of resin injection

LEDs under the mold shows the injected resin more clearly.

Injection movie

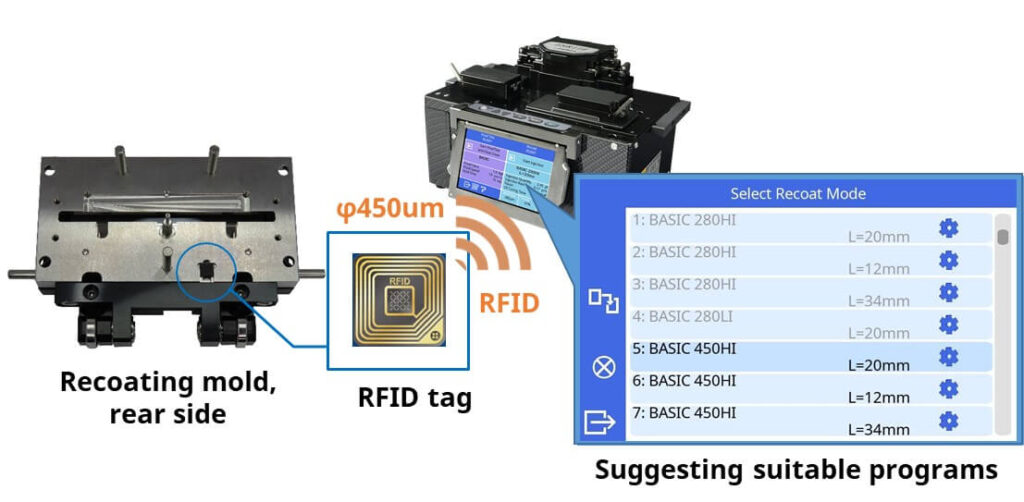

Recoat mode suggestion function

The new molds are equipped with RFID tags on the bottom of the mold. The FSR115 series scan the RFID and suggest suitable programs according to the RFID data. This improves our customers efficiency when changing molds.