Features

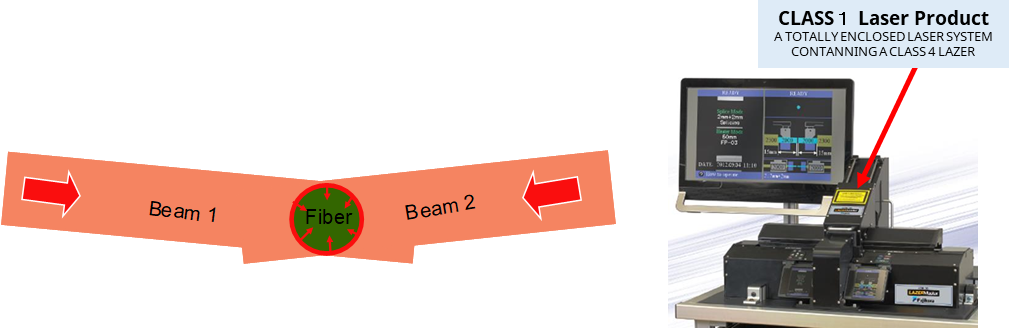

CO2 laser as heating source

- Cleanest and lowest maintenance heating source available

- Class 1 laser safety enclosure with triple redundant interlock

- Dual split laser beam from a stabilized CO2 laser to achieve uniform heating

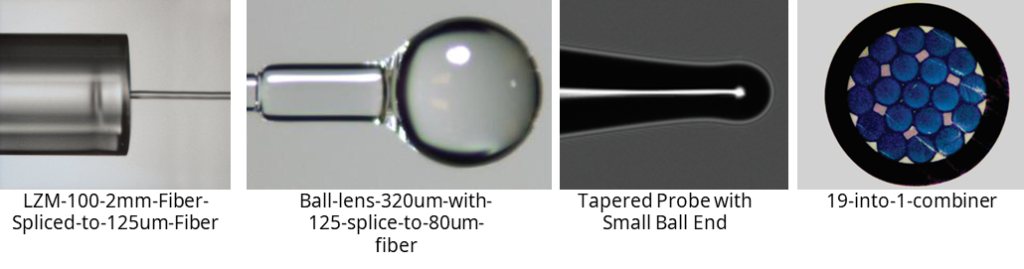

Advanced Glass Processing Application

An advanced, configurable system capable of producing tapers, ball lens, combiners, MFA, TEC, glass shaping, and splicing.

Clean & Stable Heating by CO2 Laser

The LZM-100 uses a CO2 laser heat source to heat fibers, ensuring repeatable performance and low maintenance, and eliminating electrode or filament maintenance and instability. CO2 laser heating also eliminates any deposits on the fiber surface that might occur from use of a filament or electrodes. The very clean and deposit-free fiber surface ensures reliable operation of very high power fiber lasers or power delivery systems.

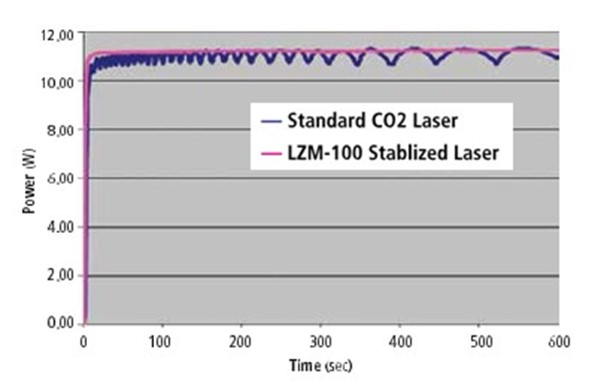

Laser Power Stability

Typical CO2 lasers have an output power

fluctuation of +/- 5%. This produces

inconsistent splicing results and may cause

irregularity and ripple in a taper profile.

The LZM-100 utilizes proprietary (patent

pending) closed-loop power stabilization

techniques, resulting in power stability

within 0.5%, as shown to left. This enables

highly repeatable processes.

Advanced Adiabatic Tapering Capability

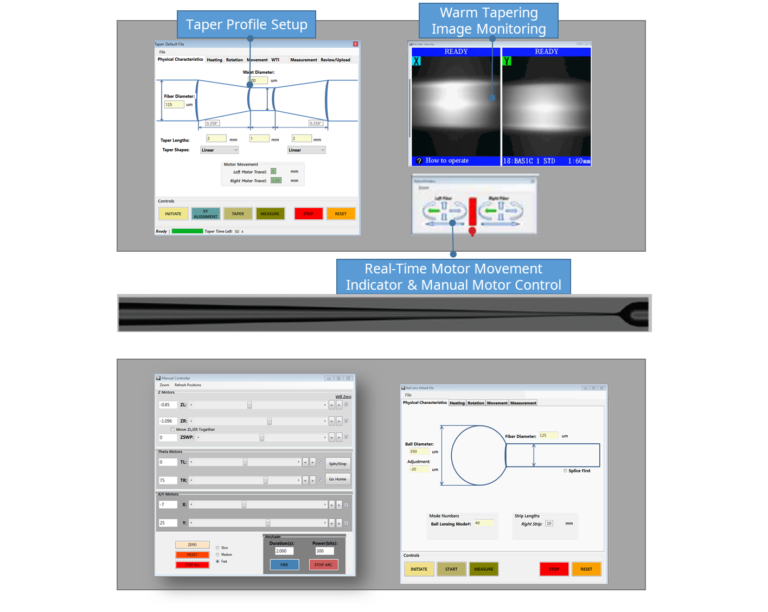

User-Friendly Tapering Graphical User Interface