Features

Quick and Safety Automated Stripping

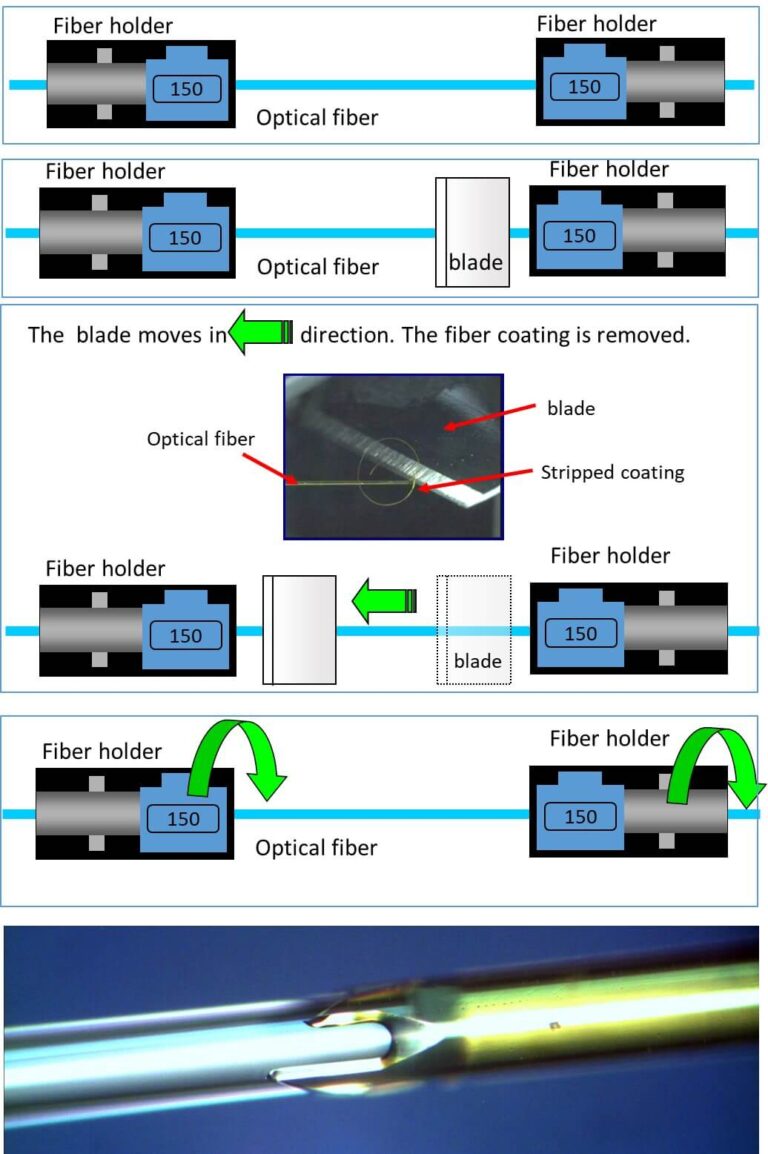

A blade is applied to the fiber with a specific tension, and the coating is precisely planed along the fiber automatically. The process is much less time consuming than any conventional methods with acid or heat.

Operation is much safer as this uses no chemicals, while the fiber reliability remains high as the glass surface is not oxidized by burning.

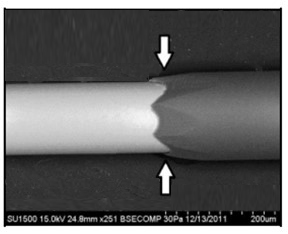

The coating edge when processed takes on a beveled shape which can be very helpful depending on the following process for the fiber.

Adjustable Parameters

A lot of parameters, such as razor blade position, stroke, and fiber rotation angle are all adjustable for various sizes and coating materials of optical fibers.

Process of Stripping

| Standard package | ||

| Item | Model | Qty |

| Polyimide Coating Stripper |

PCS-100 | 1pc |

| AC Adapter | ADC-15 | 1pc |

| AC Power Cord | ACC-xx 01 JP 02 USA 03 UK 04 EU 05 AUS |

1pc |

| Fiber Holder | FH-100-150 | 1pair |

| Instruction Manual | M-PCS100-E | 1pc |

| Blade | PCB-01 | 1pc 50 pcs / box For replacement |

| Hexagonal Wrench | HEX-01 | 1pc For blade replacement |

| Options | ||

| Item | Model | Note |

| Fiber Holder | FH-100-xxx | Fiber Holder for FSM- 100 series xxx : Coating diameter 60 ,100, 125, 150, 180, 210, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1100, 1200, 1300, 1400, 1500, 1600, 1700, 1800, 1900, 2000 μm -EV is Fiber Holder for End-view observation system |

| FH-100-***-EV | ||

| Blade | PCB-01 | 50 pieces of 1 box, for replacement |