CT-50 Fiber Cleaver

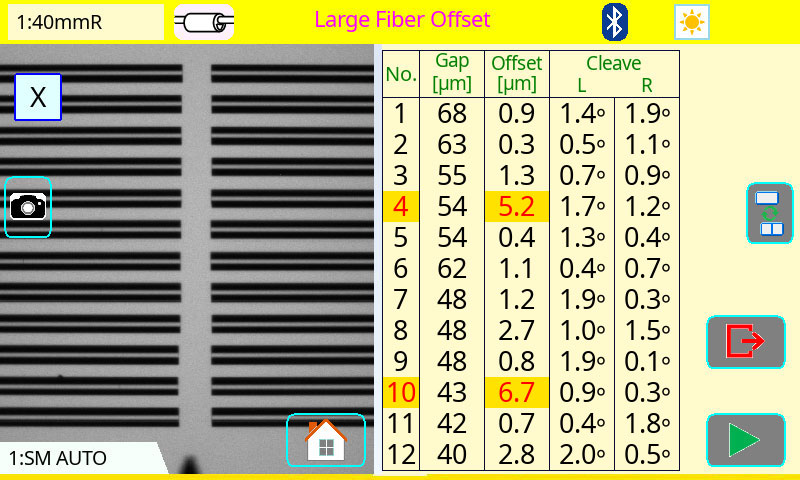

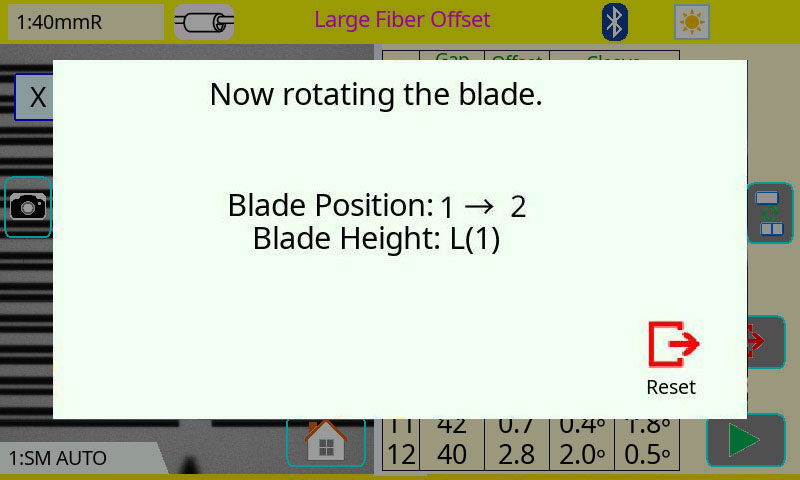

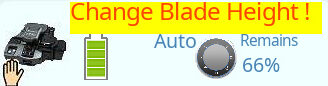

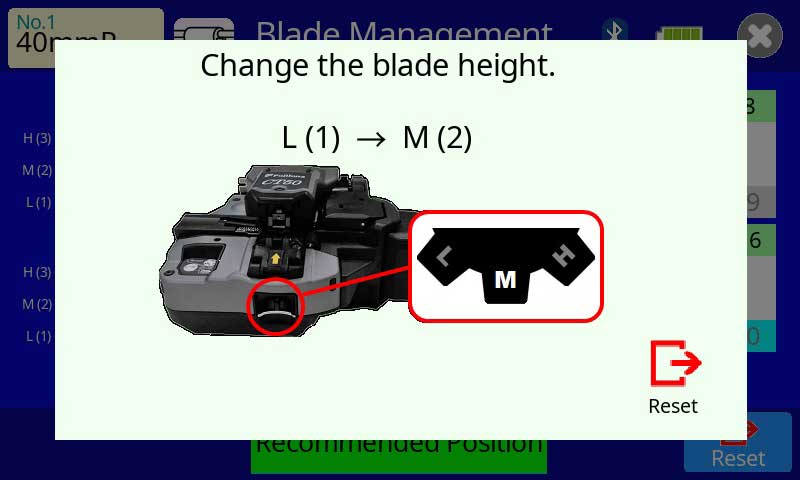

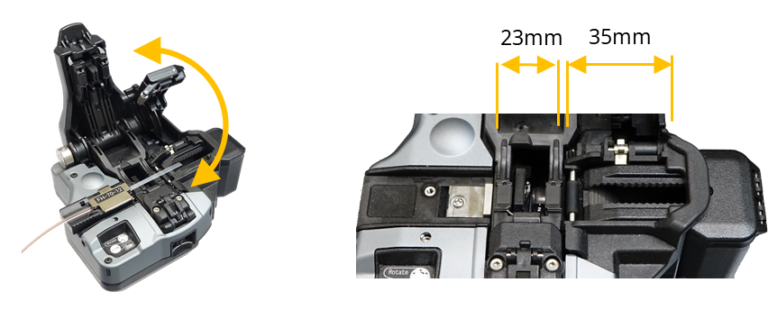

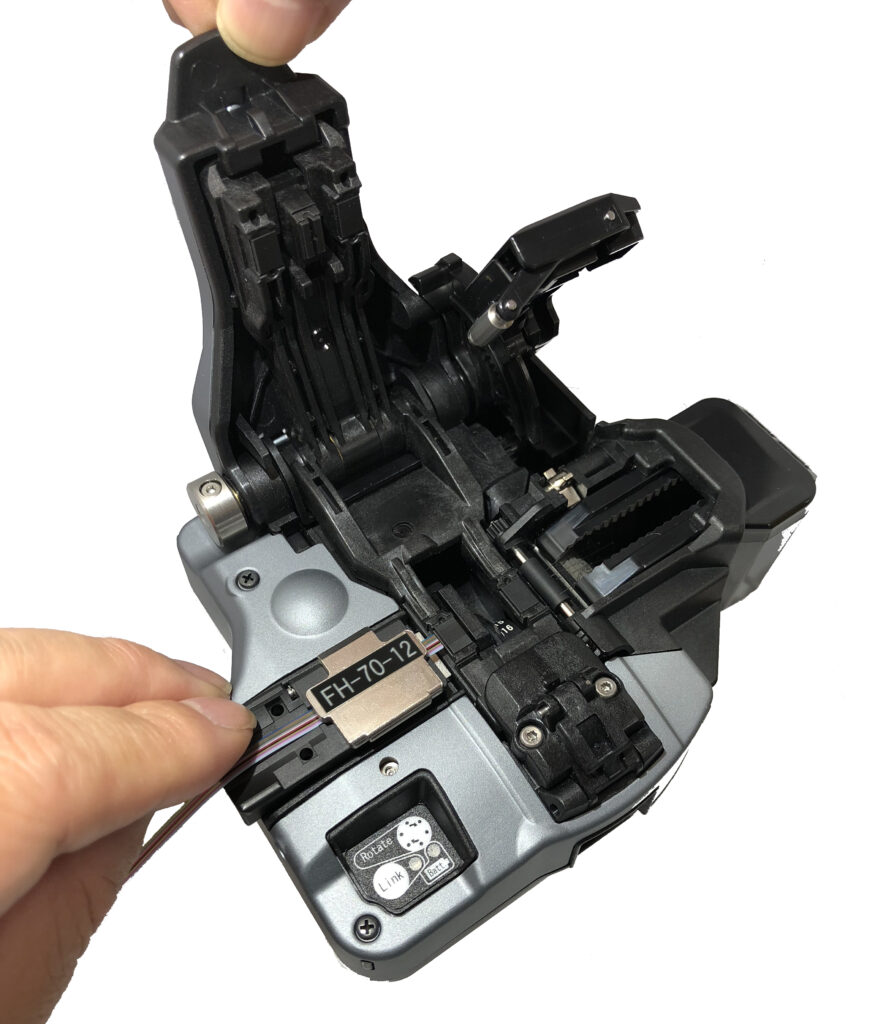

The CT50 offers enhanced drop impact resistance compared to existing cleavers and allows workers to replace the cleaver blade, providing customers with a drastic reduction in handling time and maintenance costs. The CT50 changes the position of the cleaving blade automatically and in response to the cleave quality of the optical fibers as seen by the fusion splicer. The fusion splicer will then rotate the blade once it deems the quality is poor. In addition, the CT50 completes cleaving of the fiber and scrap collection in the same step.